Sithe Chopper Pumps

SITHE Chopper Pump is a versatile and efficient solution that will solve clogging problems in any application… saving time, money, and resources.

Industry Leading Warranties

We're excited to introduce our enhanced envie3 and Razor product lines with industry-leading warranties for your peace of mind. Our envie3 products now boast an impressive 5-year warranty, while our Razor Grinder pumps come with a robust 3-year warranty. These warranties reflect our unwavering commitment to delivering high-quality, reliable, and innovative solutions that are built to last. Your confidence in our products is our top priority, and we're here to ensure your installations and projects are worry-free.

Watch us chop!

Tried and True Chopping Performance with

NEW MOTOR TECHNOLOGY: INTRODUCING THE ENVIE3

Chopper pumps are Barnes’ and Deming solution to highly demanding waste-water applications, specifically for collection systems and treatment plant applications. Chopper provides superior solid size reduction, high reliability, ease of servicing, and low life cycle costs. The chopper features the option to select either an oil-filled or air-filled motor, whichever suits your application best. Both options solve clogging with a unique, first-of-its-kind, patented chopping technology that slices even the most troublesome solids in the waste stream. This premium efficient IE3 motor delivers significant energy savings and is easy to service. The dry-run submersible motor combined with our proven chopping hydraulic performance can handle anything thrown it's way. Whether you choose an oil-filled chopper or an air-filled chopper envie3, you can put your mind at ease knowing that pump clogging is under control.

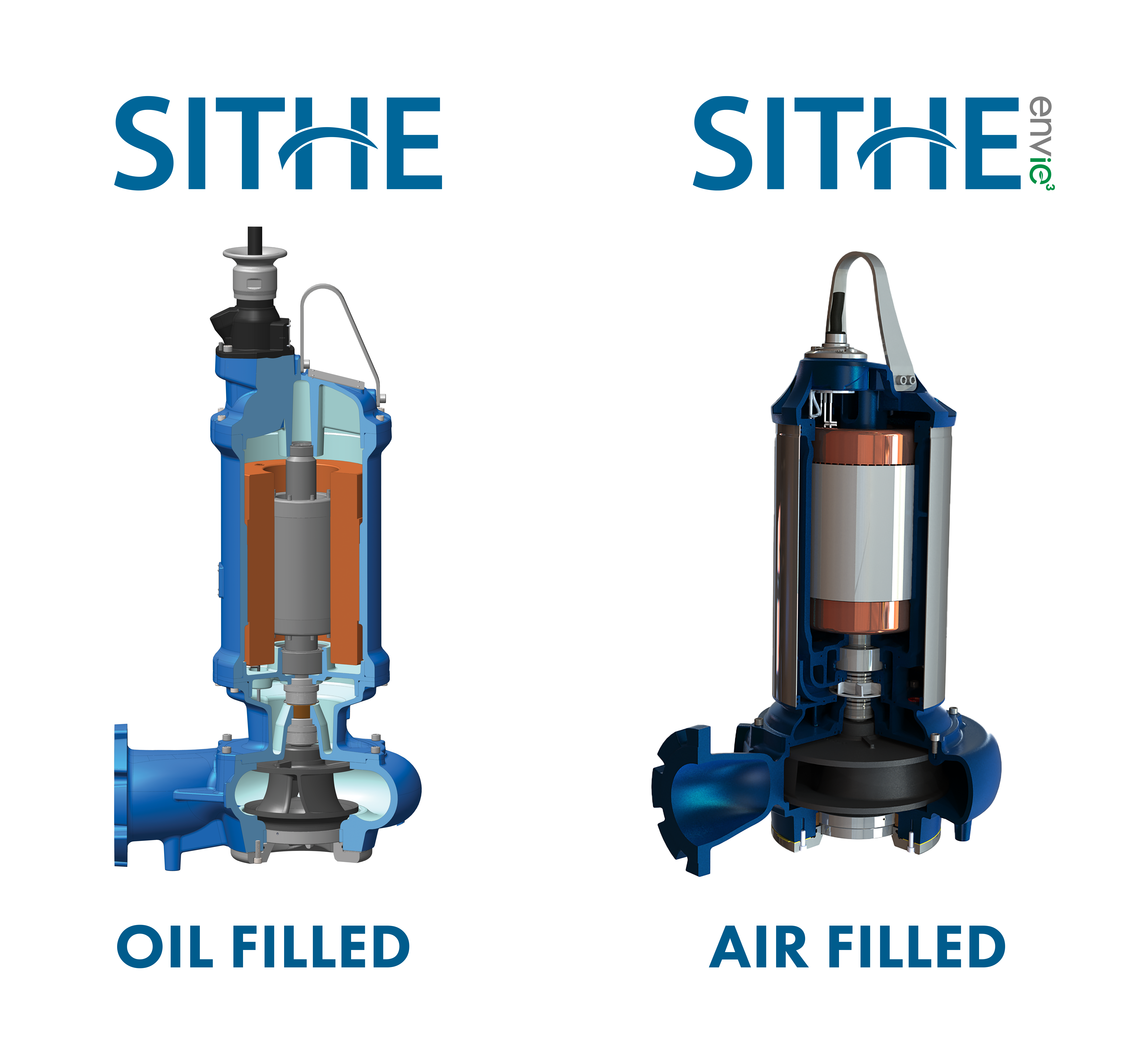

Oil vs Air Filled Motors

Our chopper platform features oil-filled or air-filled motor housings.

In the oil-filled offering, the oil acts as both a lubricant and coolant, circulating oil through the stator and housing as a heat conductor.

In the air-filled offering, envie3, the pump utilizes a glycol cooling system. This patent-pending cooling system gives envie3 the capability to operate in dry-pit applications and allows lift stations to be shallower. This feature as well as the high efficiency IE3 rating will save time, money, and resources.

There are benefits to both offerings that can be adapted for any need or application. The main difference between the oil filled chopper and air-filled chopper is how the motor is cooled. The slicing mechanism and wet end of the two models are identical to provide the long-lasting reliability of all Barnes and Deming products. Whether an oil filled chopper or an air-filled chopper better fits your application, you will experience cost and time savings.