Engineers

Looking for System Design Support for Reliable Residential Grinder Pump Stations?

Hydraulic System Design

Our Pressure Sewer Specialists have the expertise to support system design in challenging applications including seasonal usage, extreme weather, floodplain applications, re-pump applications and more! Complimentary hydraulic design services allow us to provide all the design support you require to help minimize upfront infrastructure costs by as much as 60% compared to gravity systems.

The report we provide you will include:

- Color coded pipe layouts

- System design

- Design specifications

- Design consultation

- Budgetary estimates

- Product drawings and specifications

Whether you are planning for a new construction or replacing an old system, our team can provide you with an analysis to make you confident in your investment!

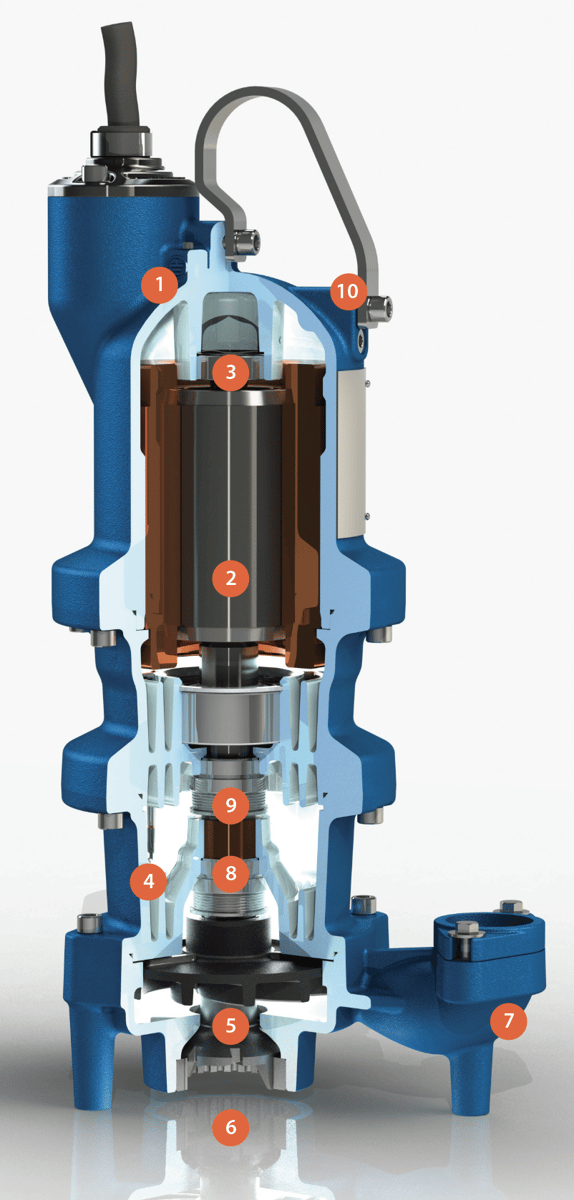

Pump Design

- Plug-n-play cord simplifies service

- Oil-Filled Motor for optimal motor cooling and maximum bearing life

- Stainless steel hardware provides resistance against corrosion to extend pump life

- Simplified hardware requires only one standard tool for service

- Axial Cutter design greatly reduces clogging issues due to troublesome objects

- Available in multiple discharge configurations for simple installation and replacement

- Heavy duty, oil-lubricated bearings extend pump life

- Oversized stainless steel lifting bail and lighter weight allows for easy installation by hand or hoist

- Two stage impeller design ideal for pressure sewer applications (single stage model is also available)

Package Options

-

-May-23-2023-07-07-03-4779-PM-1.png?width=1474&height=1080&name=MicrosoftTeams-image%20(1)-May-23-2023-07-07-03-4779-PM-1.png)

EcoTRAN – For an easy to install, standardized solution – the EcoTRAN polypropylene basin package offers field adjustable riser and inlet positioning, easily accessible components for service and an aesthetically pleasing design – providing an adaptable solution, perfect for large install bases.

-

Fiberglass Basin – For a customizable solution – the Barnes fiberglass basin package offers simplex and duplex configurations with flexibility in size, and equipment – providing the variability to select equipment suitable for each unique installation.

-

-May-23-2023-07-07-21-5073-PM-2.png?width=1406&height=1080&name=MicrosoftTeams-image%20(2)-May-23-2023-07-07-21-5073-PM-2.png)

Upgrade Core – For a drop-in replacement – the Barnes Upgrade Core offers compatible discharge connection and quick connect cords – providing a drop-in ready package that fits directly into E/One 200, 2000 and Extreme D-series stations.

* E/One® is a registered trademark of Environment One Corporation and is not affiliated with Barnes Pumps.

Pump Design

- Plug-n-play cord simplifies pump installation with its quick disconnect capability

- Oil-Filled Motor for optimal motor cooling and maximum bearing life

- Stainless steel hardware provides resistance against corrosion to extend pump life

- Moisture detection probe alerts pending seal issues before water can enter the motor

- Vortex impeller design greatly reduces clogging issues due to troublesome objects

- Exclusive Slicerator™ slices with the full torque of the motor acting on a small area to provide the ultimate solution in solids reduction

- Available in vertical or horizontal discharge for simple installation and replacement (18 frame only)

- Double mechanical seals provide maximum motor protection

- Heavy duty, oil-lubricated bearings extend pump life

- Large lifting Bail allows for easy installation

- Optional explosion proof design gives an added peace of mind for pump operation and safety; Class I Division 1 Groups C & D motors

Want to schedule training with a Pressure Sewer Specialist?

Want more information?